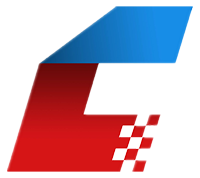

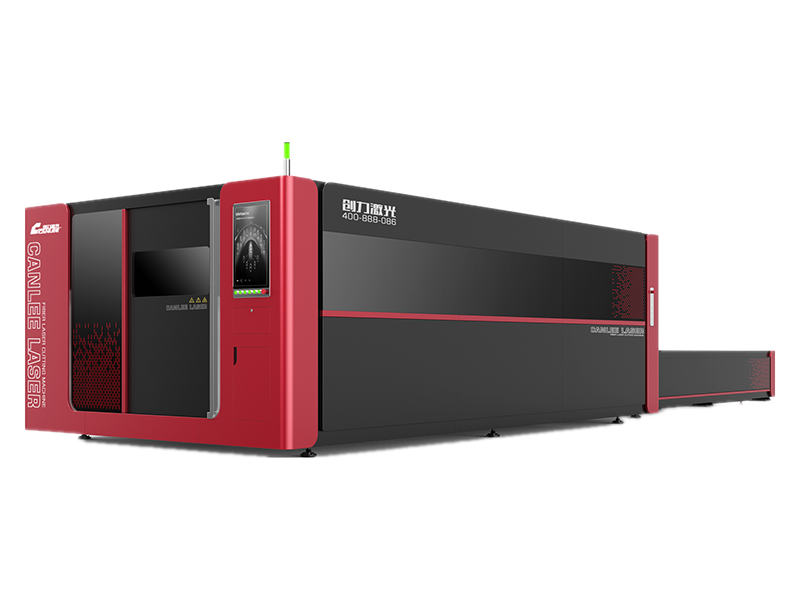

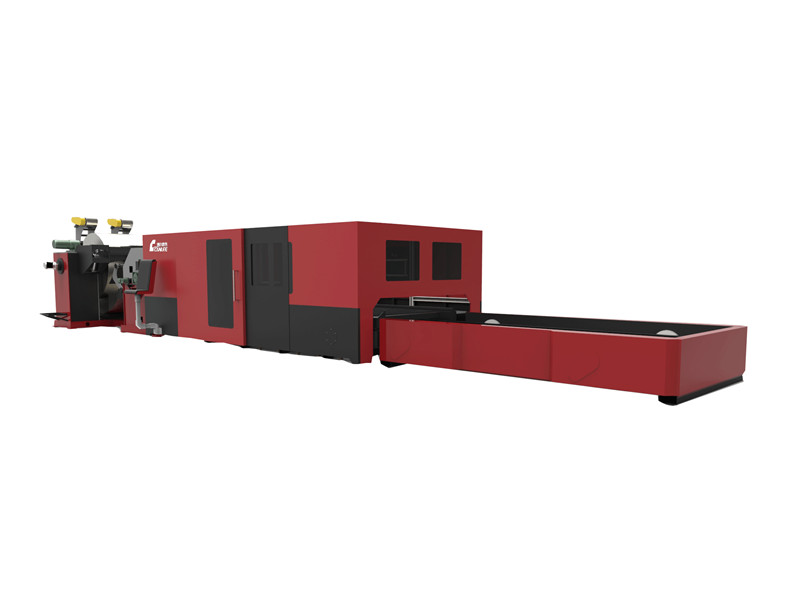

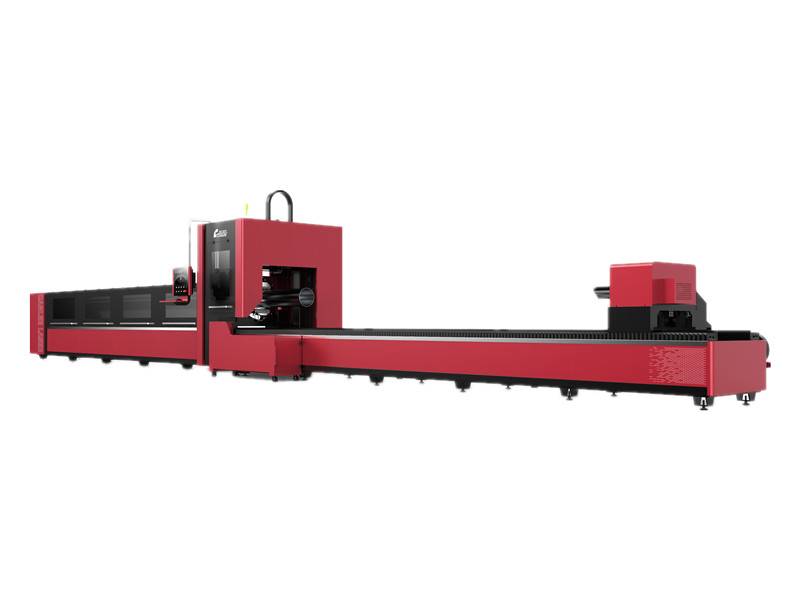

Crocs single table laser cutter

4.The numerical control system writes the human-computer interaction interface, which is suitable for multi-language control software, making the operation simpler, more convenient and more intuitive.

5. Laser: Raycus & Maxphotonics & IPG.

6. Independent cantilever console.

7. The electric control cabinet is installed at the rear, which makes the operation and parameter debugging safer and more convenient.

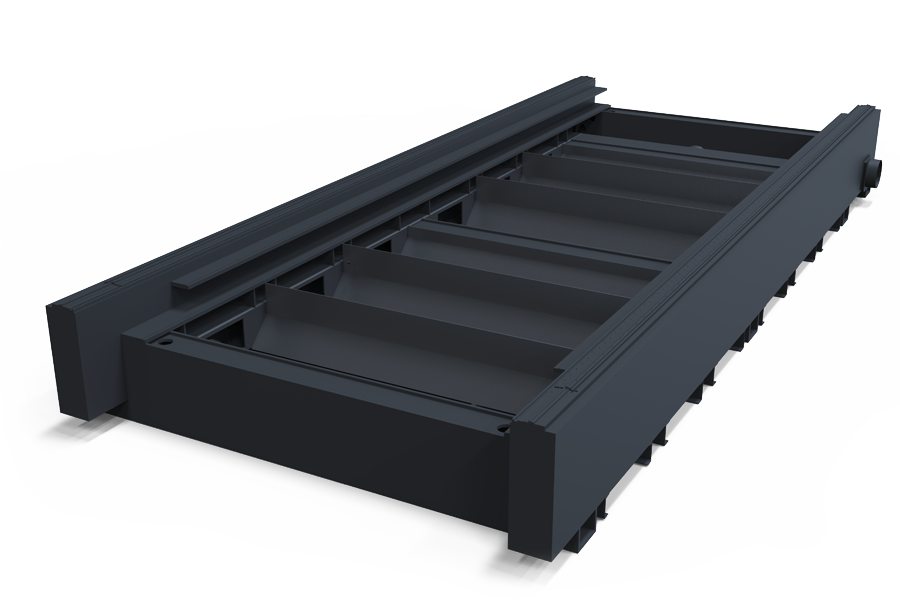

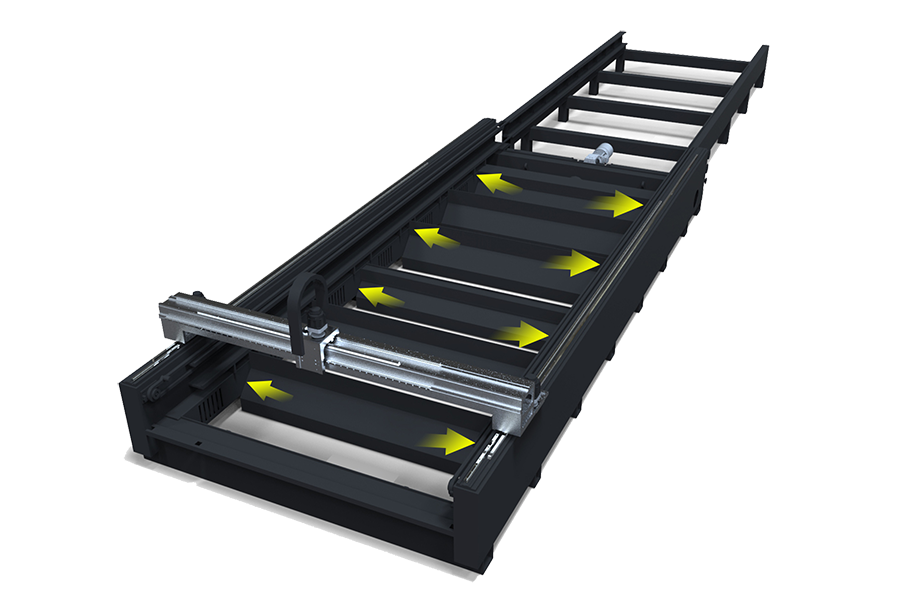

8. The dust removal structure of the base part adopts a special design device. Make the dust removal is very close to the bottom of the cutting area, improve the dust removal efficiency, avoid the laser cutting beam, and ensure the service life of the dust removal device.

The machine bed use the pipe and plate welding together, itself the weight is high, frame stable, ensure the operating well.

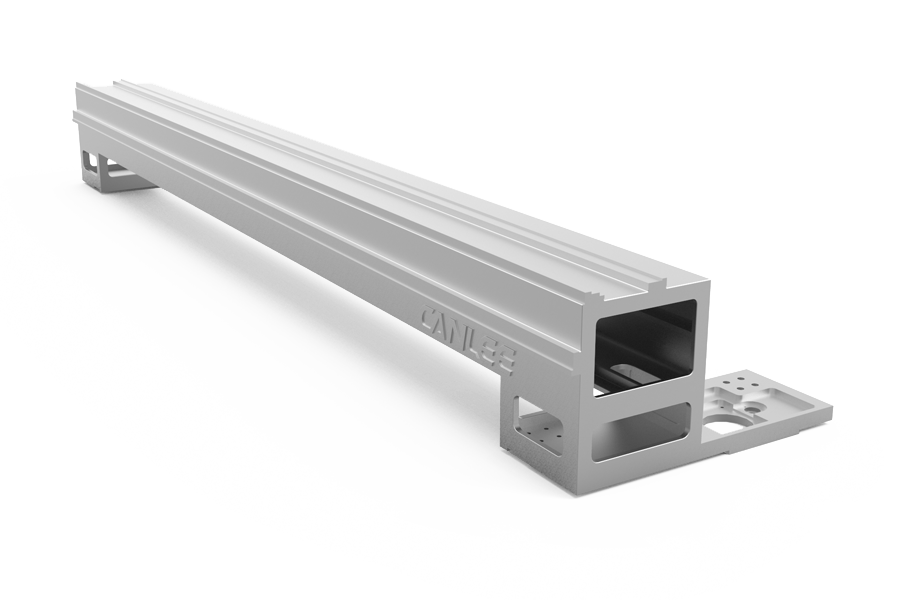

The beam refer the cast aluminum,weight is lighter, high precision and ductility.

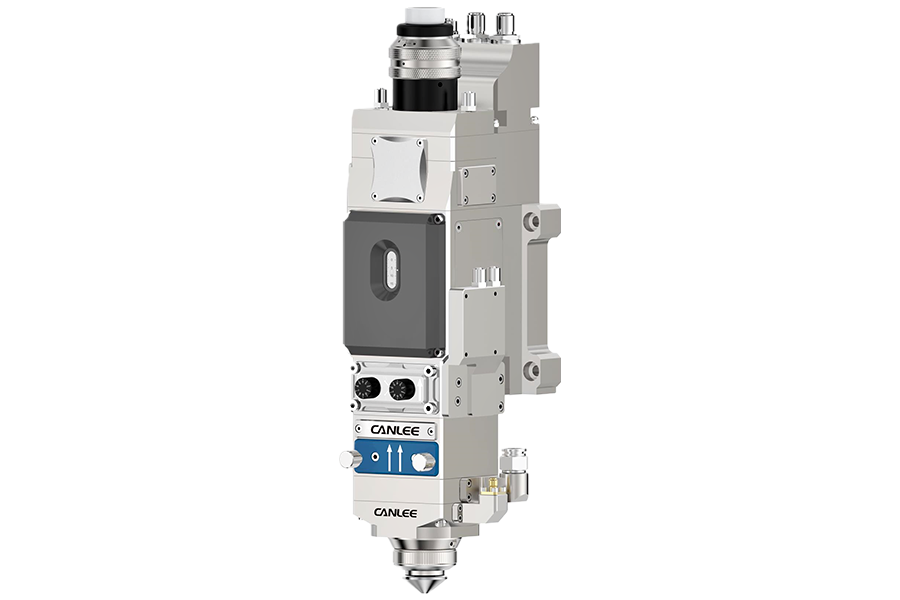

CANLEE automatic adjust focus point cutting head. It won’t demand the manual attend the light focus adjustment. Weight is lighter than past products.

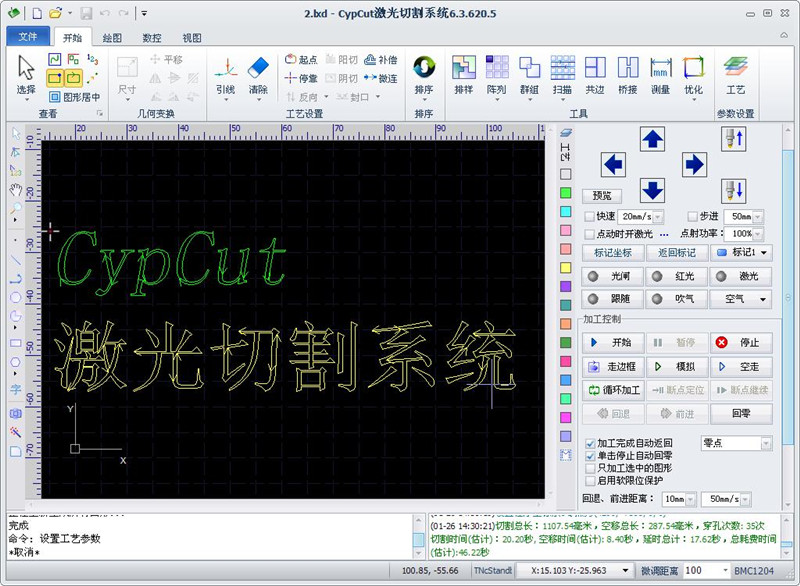

Software use the Cypcut operating controller. Cutting speed is quickly and Good compatibility .

Power source we always use Raycus&Max photonics.

Electric control cabinet set in the rear of the machine frame bed.

Each section of the bed is equipped with a fume exhaust device to accurately exhaust the smoke, effectively filtering out harmful gases, smoke and dust.

Technical parameters

|

Model |

CF-3015F |

CF-4015F |

CF-6015F |

CF-4020F |

CF-6020F |

Customized Machine |

|

Cutting Range (mm) |

1500x3000 |

1500x4000 |

1500x6000 |

2000x4000 |

2000x6000 |

1500-3300x 3000-14000 |

|

X Axis stroke (mm) |

1525 |

1525 |

1525 |

2050 |

2050 |

|

|

Y Axis Stroke (mm) |

3050 |

4050 |

6050 |

4050 |

6050 |

|

|

Z Axis Stroke (mm) |

100 |

100 |

100 |

100 |

100 |

|

|

XY Axis Positioning Accuracy(mm) |

±0.03 |

±0.03 |

±0.03 |

±0.03 |

±0.03 |

±0.03 |

|

Repeat Accuracy(mm) |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

0.02 |

|

Laser Power(W) |

1000/1500/2000/3000/6000/8000/12000/20000 |

|||||